plate filter press

The plate filter press is a kind of press filter equipment which applies to solid-liquid separation of all suspension and is able to accompany the oil press. We supply a wide range of filter presses designed to give maximum filtration efficiency, longer service life and less maintenance. The filter presses are available in different sizes and various capacities. We can also provide filter presses to custom specifications.

GEMCO is professional in producing separation equipment and filter and belt press filter are its main series. The types of filter are 200,320, 450, 630, 800, 1000, 1250, 1500, Φ800 and Φ1000 and both in board and box and the filter area is 0.5㎡-500 ㎡. The materials for board choice are cast iron, ductile iron, reinforced polypropylene, glass fiber polypropylene ( temperature 120℃) and stainless steel. The press methods are handle press, jack press, mechanical press, liquid press, automatic pressure press and advanced automatic microcomputer control. The ways for filter are free flow, undercurrent flow, free flow wash out, undercurrent flow wash out and two-way cross wash. The Polypropylene has the advantages of stable performance, acid and alkali proof, non-toxic, non-smell, non-pollution and easy to handle. The filter series of our company accord with the national and related industrial regulations (see in technical parameters) and also be produced according to the customers’ special needs. Our products are qualified and have passed the ISO9002 registration.

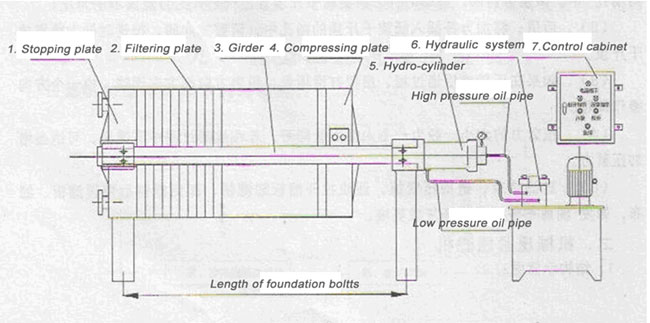

Plate Filter Press Structure

The filter is formed by four parts:Mainframe, filtering parts, press and control.

2.Filter: The filter part is constituted by several filter boards and frames which are ranked in the main beam in an order—the filter is between filter board and frame. When material come into filter room from hole in push plate, the solid bigger than the hole of filter intermediary is hold in the filter room and become solid lump while the liquid flow out from the discharge hole by free flow and undercurrent flow. Under each filter board there is a hole with a water nozzle that the water flow out from the nozzle is called free flow, while the way brings water from each filter boars together and flow out by discharge channel is called undercurrent flow.

The filtering Part of the equipment:

3.Press Parts:

The press parts can be divided into handle press, jack press, mechanical press, liquid press and automatic pressure press.

- Handle press and jack press: The function of handle press is to turn the small gear to drive the large gear so as to press clamping plate, using lever force from small gear to drive the pole in large gear. One person can do that while the jack press uses direct way.

- Mechanical press: Based on the motor, through reducer the mechanical press drives the pole of large gear to press the clamping plate. Forward and backward is by switching the button. This method cannot be displayed directly and it is controlled by the electrical equipment. When electricity reaches the rated the machine stops, and all machines have appropriate electricity before leaving factory.

- Liquid press:The liquid press system depends on motor to drive oil pump, and pressed oil entry into oil cylinder through control valve then piston or piston pole tightens or drags the press plate to achieve press. The methods for liquid press are handle, electrical, automatic pressure and program-automatic pull plate.

Plate Filter Press Working Principle

The filter chamber is formed by filter boards and filter frames or filter boards rows (box-type), under the function of conveying pump, it press the suspension liquid into filter rooms and through filter intermediaries (filter cloth, filter paper and filter membrane) to separate solid and liquid. What is more, the box-type filter boards can be classified into common boards and diaphragm boards. The filter can be used wildly in petroleum, chemical industry, medicine, sugar, metallurgy, food, china, starch, coal washing, dye, and paint as well as sewage treatment in all industries.

BAM Series Plate Filter Press and Technical Data

| Model | Filtering Area(㎡) | Capacity of the filtering chamber(L) | Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

| BAMS1/320-30U | 1 | 15 | 1210*660*650 | 350 | 710*150*500 |

| BAMS2/320-30U | 2 | 31 | 1565*660*650 | 400 | 1020*150*500 |

| BAMS3/320-30U | 3 | 46 | 1875*660*650 | 455 | 1330*150*500 |

| Model | Filtering Area(㎡) | Capacity of the filtering chamber(L) | Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

| BAMS4/450-30U | 4 | 61 | 1940*870*870 | 720 | 1160*180*600 |

| BAMS6/450-30U | 6 | 91 | 2250*870*870 | 800 | 1470*180*600 |

| BAMS8/450-30U | 8 | 122 | 2560*870*870 | 880 | 1780*180*600 |

| BAMS12/450-30U | 12 | 182 | 3160*870*870 | 1020 | 2380*180*600 |

| BAMS16/450-30U | 16 | 243 | 3770*870*870 | 1180 | 2990*180*600 |

| Model | Filtering Area(㎡) | Capacity of the filtering chamber(L) | Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

| BAMJ20/630-30U | 20 | 298 | 3400*1150*1160 | 1980 | 2490*400*800 |

| BAMJ30/630-30U | 30 | 453 | 4220*1150*1160 | 2350 | 3310*400*800 |

| BAMJ40/630-30U | 40 | 595 | 4950*1150*1160 | 2680 | 4040*400*800 |

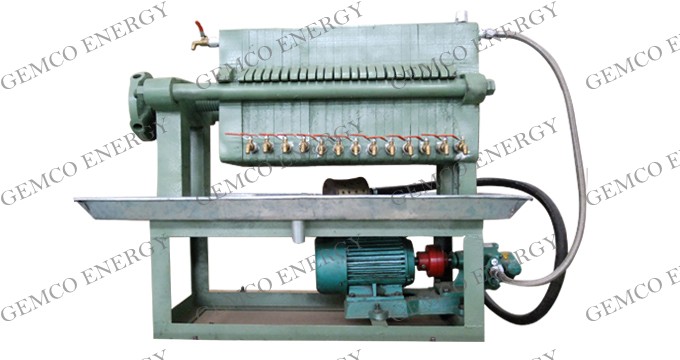

6LB Series Plate Filter Press

6LB Oil Filter Technical Parameters

|

Model

|

No.oil filter plates

|

Dimensions of filter plate

|

Working pressure

|

Productivity

|

Power

|

Dimension

|

Weight

|

|

6LB-250

|

13pcs

|

250*250mm

|

0.3-0.4MPa

|

100kg/h

|

0.75Kw

|

780*530*670mm

|

155kg

|

|

6LB-350

|

25pcs

|

350*350mm

|

0.3-0.4MPa

|

200kg/h

|

1.1Kw

|

1300*750*700mm

|

470kg

|

PROCUTS

- small oil press

- YZS-100 oil press

- YZS-120 oil press

- YZS-30 automatic oil press

- YZS-70 automatic oil press

- YZS-95A automatic oil press

- YZS-120A automatic oil press

- YZS-130A automatic oil press

- ZX-95A oil press

- ZX-130 oil press

- YZS-68 oil press

- YZS-80A automatic oil press

- YZS-80 oil press

- YZS-95 oil press

- YZS-100A automatic oil press

- YZS-130 oil press

- big oil press

- plate filter press

- manual oil press

- soybean extruder

- What's the Main Filtering Method in Edible Oil Processing Plant?

- difference between small oil press and big oil press

- Mustard Oil Mill Machinery

- LYZX24-1 Oil Presses

- Oil Pressing Plant

- Palm Kernel Oil Press Machine

- Walnut Oil Press Machine

- screw oil expeller with big capacity

- large oil press

- Peanut Oil Mill